Posts Tagged ‘Energy Efficient’

- In: HVAC

- Leave a Comment

Building owners are often faced with decisions that carry either heavy consequences or sweet rewards and regardless of the function of a building, nine times out of ten it will need air conditioned space in some form or fashion. Because of this inevitability the decisions one makes in regards to their HVAC system can have a substantial impact on the financial landscape of their business and becomes even more prevalent the larger the footprint of the building. Either way, regardless of the size of the building, it is vital to make smart decisions regarding your HVAC system and Building Automation System.

Whether you are wearing “The Golden Handcuffs”, as I wrote about in a previous article, or you have a dying pneumatic system that desperately needs to be upgraded, there is a way to accomplish this daunting and sometimes intimidating task without sinking the ship financially. I call it “The Slow Play”. All too often building owners will be led to believe that they need to “Rip and Replace” their entire control system in one fail swoop in order to make the necessary upgrades. This simply is not true.

With our Tridium Niagara offering we can migrate an entire HVAC system one piece at a time without interrupting the operation and functionality of the existing system. Being able to offer this to our customers allows them to preserve precious cash on hand while still moving forward with the renovation. For example, let’s look at a building with ten Air Handlers, sixty VAV boxes, two Chillers, two Boilers and five Exhaust Fans. While there are endless as well as differing combinations of equipment from building to building, this example will at a minimum, allow us to step through “The Slow Play” process.

First, we will integrate the Chillers and Boilers because the majority of the other equipment in the system hinge on the functionality of these two vital pieces of equipment. After we have the Central Plant equipment under control we will turn to the Air Handling Units. The VAV boxes that are served by each Air Handler need to be identified because we will be integrating those boxes along with the Air Handler as one single system. For example, AHU-1 serves VAV boxes 1 through 6 so for this phase we will only be integrating those pieces of equipment. We will continue in this fashion until all of the AHU’s and VAV’s have been converted. After we have all of the major equipment rolled over to the new system it is fairly easy to move over the rest of the auxiliary equipment in the building such as exhaust fans, lighting panels, etc.

Typically, this work will be done after hours, on weekends, or at a time that has the least amount of impact on tenant space comfort. Some building owners may choose to implement each phase on a monthly basis, quarterly basis or even a yearly basis. Regardless of the time period they choose to spread it out across, the value lies in the ability to not only methodically integrate the entire system without interrupting existing functionality, but most importantly, break out the cost of the new system into manageable amounts.

Here at HTS we are not interested in leading our customers down a path that only benefits our interests and our goals, but rather a team approach that benefits everyone involved and builds a relationship that both parties can rely on for years to come. So if the fear of cost is holding you back from upgrading your Building Automation System then give HTS a call and let’s tailor your very own “Slow Play” gameplan.

-Shane Ray, North Texas BAS Manager

You are a building owner and you have just bought a new Building Automation system for your building. Promises of energy savings, higher efficiency and lower maintenance costs were a major factor in your decision to upgrade your building. You have seen the studies and reviewed the data extensively and are confident that you made the right decision. All you can think about is how much money you will save on your energy bill due to your recent purchase.

While all of these claims are accurate and there is definitely tremendous value when investing in an automation system there is one caviot that building owners often overlook. While most prudent business owners will factor in the cost of maintenance and service, they often discount the lack of flexibility this new relationship offers or are completely unaware of what waits around the corner.

For many years controls contractors used what is called a proprietary protocol. Before Bacnet and Lonworks and even still today, each company had their own communication protocol that made it impossible for anyone else to service the system. You HAD to use the company that installed the system. This meant that the owner was now at the mercy of the installing contractor. You need a $10 part replaced? Sure that will be $2,000 for us to come replace it. You need a $200 board replaced? No problem – that will be $4,500. And let’s not forget the blistering speed of technology. You need a software upgrade – a function that literally takes a technician a couple clicks of the mouse and 10 minutes to execute – that will be $5,500.

The great deal that you got on your new Building Automation system that, according to the smooth talking salesman, “pays itself off within 3 years and lowers your electric bill and makes your building run more efficiently” is now costing you an arm and a leg to maintain and service. Not to mention you can’t get a technician to come fix anything in a timely manner. “We have you in the Q and we will dispatch a tech as soon as one comes available” is what they tell you. So not only do you have to pay outrageous service fees but you have to limp along until someone can actually come fix the problem.

This scenario is all too familiar to many building owners across not only Texas, but the entire country. We call this “The Golden Handcuffs”, and when you get Golden Handcuffs put on you they are very hard to take off.

HTS has heard your cries for help and we have a solution that puts the power back in your hands. The days of being a victim of your building automation system are over. We offer a completely open protocol system that not only matches up to the proprietary lines but far exceeds their functionality and flexibility. The Tridium Niagara front end gives the luxury of choice back to the customer and with over 300 drivers available we can seamlessly integrate any system. The days of paying $2,000 for a sensor are over. No matter how tight they may have put the golden handcuffs on you, we can take them off.

HTS has heard your cries for help and we have a solution that puts the power back in your hands. The days of being a victim of your building automation system are over. We offer a completely open protocol system that not only matches up to the proprietary lines but far exceeds their functionality and flexibility. The Tridium Niagara front end gives the luxury of choice back to the customer and with over 300 drivers available we can seamlessly integrate any system. The days of paying $2,000 for a sensor are over. No matter how tight they may have put the golden handcuffs on you, we can take them off.

So give HTS a call because we have the key to the “Golden Handcuffs”!

-Shane Ray, North Texas BAS Manager

Taking LEED

Posted on: July 29, 2015

- In: HVAC

- Leave a Comment

We know you know what LEED is, why it’s beneficial to the environment and how building green results in tax credits, lower energy bills and faster payback. You probably even know that our energy efficient equipment helps contribute to LEED points. What you may not know though is how exactly we help your project earn those points and what areas on the scorecard we can affect.

Our reach

We can control up to 20 points of the LEED Requirement utilizing HTS suite of products and services. With our vast experience of LEED projects and LEED AP staff, we can also research and identify points in the innovation and design category that have been implemented in the past that can add to your particular project objectives.

With over 90 LEED projects under our belts (many on this list of Houston’s Platinum projects), we know exactly how to optimize system design to earn you the most points toward your accreditation.

Where we score

Energy and Atmosphere (up to 13 points)

- Minimum Energy Performance – we will do all the calculations for the MEP design engineer (Prerequisite)

- Fundamental Refrigerant Management (Prerequisite)

- Optimize Energy Performance – Achieve 25-30% HVAC operating energy reduction compared to ASHRAE 90.1 baseline using Daikin magnetic bearing centrifugal chiller technology, Daikin Premium efficient fan technology (powered by AcoustiFLO), Daikin Energy Recovery Airside Equipment, and Dynamic Polarized Filter Technology (Up to 10 points)

- Enhanced Refrigerant Management (1 point)

- Measurement and Verification, Base Building (1 point)

- Measurement and Verification, Tenant Sub Metering (1 point)

Indoor Environment Quality (up to 7 points)

- Minimum IAQ Performance

- Outdoor Air Delivery Monitoring (1 point)

- Increased Ventilation (1 point)

- Construction IAQ Management Plan (1 point)

- Low Emitting Materials – adhesives and sealants (1 point)

- Indoor Chemical and Pollutant Source Control (1 point)

- Controllability of Systems, Thermal Comfort – overhead chilled beams or underfloor air (1 point)

- Thermal Comfort in Design (1 point)

See our list of LEED accredited projects here and contact your local HTS office to further discuss your project’s LEED objectives.

Our summer road trip across Texas

Posted on: July 17, 2015

In the spirit of summer road trips, we’re taking a look at some of our key projects across Texas. Whatever city you’re stopping in this summer, you’re sure to spot an HTS success in our great state!

AUSTIN

Hyatt Regency

Located right on Lady Bird Lake in downtown Austin, the Hyatt Regency sits off of the iconic South Congress bridge (i.e. the bat bridge). We updated the ballroom HVAC to a quieter, more energy efficient system that could handle the fluctuating occupancy with ease. Read More…

DALLAS

Texas Health Presbyterian Plano

This award-winning hospital has been a prominent healthcare facility in Plano for over 20 years. We helped solve some complicated humidity issues occurring in the operating rooms with our team of engineers and advanced dehumidification solutions. Read more…

FORT WORTH

Kimbell Art Museum

A staple of the Fort Worth arts district, the Kimbell Art Museum attracts thousands of visitors from across the nation. With the addition of the new Piano Pavilion, we helped the museum upgrade their HVAC to meet the increased cooling demands in an energy efficient way. Read more…

HOUSTON

3009 Post Oak

You can’t miss this new 20-story office building. Located in the Galleria area, 3009 Post Oak is a LEED Platinum facility with more than 300,000 square feet of office space. We secured 8 LEED points for the project by providing a full-package, premium-efficiency HVAC solution complete with building automation controls. Read more…

SAN ANTONIO

Comstock Border Patrol Station

That’s right. Even if you happen to make it all the way down to the Texas border, you can find an HTS project. Once a drive-thru stop, the Comstock Border station recently expanded to 4 new buildings to accommodate its growing needs. We provided an entire system of HVAC solutions from chillers to airside products to an advanced building automation system. Read more…

- In: HVAC

- Leave a Comment

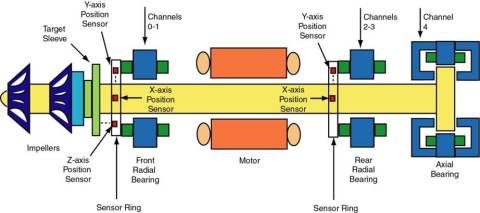

If you’re trying to create the ultimate climate-controlled environment in your office, school, or healthcare facility, the Daikin Magnitude® magnetic bearing water cooled chiller is designed to help you accomplish that! Available from 100 to 1500 tons, the Magnitude chiller offers money- and energy-saving benefits for building owners and property managers, as well as a comfortable environment for building occupants.

– Industry leading part load energy savings: Energy costs are rising, and efficiency is becoming a top priority for building owners everywhere. Saving energy means saving money, and when it comes to saving energy, Magnitude is up to 40% more efficient than standard centrifugal chillers and can save up to $4 million over the life of the chiller.

– World-class, sustainable, and reliable performance: Daikin designed the magnetic bearing compressor to improve overall performance and reliability. The single rotating compressor shaft levitating on a magnetic field eliminates mechanical seals, wear surfaces, gears and slide valves so machines last longer and run better. Magnitude is world-class in performance, sustainability, and reliability across many commercial building applications.

– Environmental commitment: Magnitude units exhibit commitment to the environment through the use of environmentally-friendly R-134a, a refrigerant that has no ozone depletion and no phase-out schedule. Magnitude also helps the environment with its oil-free design, high efficiency, and efficient use of materials, so you can help deter global warming while keeping your building cool.

– LEED® points and potential rebate qualifications: Magnitude units contribute to LEED points and in some cases, help owners qualify for responsible energy use incentives and rebate dollars. The compact size also makes the Magnitude chiller ideal for retrofit and replacement products, as the unit can fit easily through standard sized doors, making it a perfect fit for your energy upgrade projects.

– Oil-less technology allows maintenance savings: By creating a design that uses no oil, the Magnitude eliminates oil management systems for improved compressor and system reliability. The oil-free design also prevents oil contamination of heat-transfer surfaces, resulting in higher efficiency.

Overall, the Magnitude offers a great value and fast payback opportunity. In addition to energy efficiency, Magnitude magnetic bearing chillers have fewer moving parts, require no oil, nor oil-circulation equipment, and therefore require less maintenance and service to save you time and money. To learn more and view installed projects, visit http://texas.htseng.com/relinfostore/Productdetails.asp?id=247&ProductID=554.

Source: Daikin Applied

- In: HVAC

- Leave a Comment

Leading the way with LED

Lighting is one of those costs that every operating building incurs. As such, it is a great starting point for your next energy efficiency upgrade or renovation project.

With the up-front costs of LED products steadily declining, switching your lighting to an LED system is a cost-effective solution that can provide payback in 2-3 years at the earliest. While many energy-efficiency plans can take up to 15 years to see payback, this seems almost instantaneous.

LED lighting alone can cut your energy bill down, but when paired with a controls or smart lighting system, it can lead to 90% in energy savings.

A controlled lighting system works great for:

- Buildings with fluctuating populations such as schools or office buildings

- Warehouses and manufacturing facilities that require high lighting during working hours and little-to-no-light after hours

- Arenas and expo centers that have several different kinds of events that require specific lighting

Contact us today

Our HTS Service team wants to start saving you money now. Contact your local office today to start learning about how we can implement a new lighting system at your facility.

Our HTS Service team wants to start saving you money now. Contact your local office today to start learning about how we can implement a new lighting system at your facility.

- In: HVAC

- Leave a Comment

Energy efficiency. Sustainability. Green building. You’d be hard pressed not to come across these and other energy buzz words in the construction industry nowadays. This movement may seem modern, but did you know that water-source (or geothermal) heat pumps – one of the most efficient system options on the market – have been in use since the late 1940s?

For extreme climates like Texas, the water-source heat pump (WSHP) was a much needed solution to the traditional air-source heat pump system. Rather than using the outside air as the exchange medium, WSHPs use either geothermal heat or water tempered by a cooling tower/boiler. Either application uses a more constant temperature source. This creates less work for the system to output a comfortable temperature, resulting in major efficiency gains. While the technology has been around since the 1940s, vast improvements in the last 25 years have made the WSHP a viable option for all types of facilities.

For extreme climates like Texas, the water-source heat pump (WSHP) was a much needed solution to the traditional air-source heat pump system. Rather than using the outside air as the exchange medium, WSHPs use either geothermal heat or water tempered by a cooling tower/boiler. Either application uses a more constant temperature source. This creates less work for the system to output a comfortable temperature, resulting in major efficiency gains. While the technology has been around since the 1940s, vast improvements in the last 25 years have made the WSHP a viable option for all types of facilities.

Because of their use of individual units, WSHPs provide great flexibility in design. The zoning ability makes them a great fit for schools and multi-family buildings, as well as offices and hotels. Government projects also see great benefit in WSHPs as they can help meet energy requirements and contribute to LEED credits. Facilities with existing water features, like a pond, can often save money on WSHP installation as the water can be used as the heat exchange medium, rather than digging a trench to reach the earth or using a cooling tower/boiler. The durable construction of WSHPs gives them an estimated 25-year lifespan, and end-users can expect to see significant paybacks in 5-10 years.

Daikin water-source heat pumps can save energy, while also reducing design, installation and operating costs. Here is a breakdown of the benefits for all the involved parties of a project:

Owner, Engineer and Contractor Benefits

The Building Owner

■ High efficiency units reduce energy consumption/operating costs and can contribute to earning points toward LEED® certification.

■ Open Choices control feature gives you the flexibility to select standalone thermostat operation or easy, low cost integration with the BAS of your choice using an add-on communication module – keep it in the family and use HTS BAS for your controls needs

■ R-410A refrigerant has no ozone depletion potential or phaseout date, helping to minimize environmental impact and protect against refrigerant availability issues over the economic life of your equipment investment.

■ Large fan wheel, quiet compressor selections and low vibration design promote quiet operation.

■ Double-sloped polymer drain pan and optional closed cell insulation promote superior indoor air quality.

■ Durable construction promotes long life, reliable operation.

The Engineer

■ Boiler/tower or geothermal unit selections provide flexibility in designing the system that best meets the performance and budget requirements of your project.

■ Multiple configurations reduce design time and cost by allowing you to avoid obstructions and use minimum ductwork.

■ Multiple features and options (ECM motor, desuperheater, hot gas reheat, integral electric heat, painted cabinet) give you the flexibility to select units that closely match application requirements.

Installing Contractor / Service Personnel

■ Small footprint design makes it easier to meet space requirements of new construction and replacement applications.

■ Flush FTP water fittings save time in making water connections using one wrench.

■ Factory-installed filter rack saves time and expense to field-install a filter rack.

■ External LED status lights allow quick troubleshooting – no need to open up the unit.

■ Easy access to the unit compressor (2-sides), fan section (1-side), motor (1-side) and unit controls (front access).

■ A removable orifice ring allows the blower and motor to be removed without removing the blower housing or disconnecting the unit from the ductwork.

In addition to all this, the HTS parts department keeps Daikin Enfinity WSHPs in stock at most of their locations across Texas, plus provides certified factory training throughout the state. Contact your local store today to learn more about availability, pricing, shipping and training.

If you’re interested in using Daikin WSHPs for your next project or simply want to learn more about the product, contact your local HTS system representative today!

Sources: daikinapplied.com, http://lit.daikinapplied.com/bizlit/DocumentStorage/WaterSourceHeatPump/Brochures/ASP_31-249_Enfinity_Floor-Mounted_WSHP.pdf, http://energy.gov/energysaver/articles/geothermal-heat-pumps

Direct Expansion Solutions Branch Manager to Speak at CEFPI 2012 Southern Region Conference

Posted on: April 9, 2012

Joel Hill Explains How to Achieve High-Efficiency HVAC in Unaccommodating Existing Buildings

Joel Hill, branch manager of Direct Expansion Solutions (DXS) will address the Council of Educational Facility Planners International (CEFPI) on Saturday, April 14, 2012 at the organization’s Southern Regional Conference. His session will discuss system options for adapting the high-efficiency HVAC systems being used in new buildings for use in unaccommodating existing buildings.

Hill has 10 years of experience in the design and application of high-efficiency HVAC equipment. He has been involved in the design and selection of geothermal heat pumps, variable refrigerant volume, energy recovery ventilation, and control sequences used to improve K-12 school building energy performance by 40-50 percent.

The conference’s theme is “Innovate not Amputate: Turning Challenge into Opportunity.” Among the topics Hill will discuss in his presentation:

- • what makes HVAC efficient

- • ideas for addressing retrofit obstacles due to existing buildings

- • understanding the cost impact of different HVAC systems

- • helping design teams establish realistic energy-efficiency targets for retrofit schools

For the schedule and more conference information, visit www.cefpi.org. Social media-savvy attendees can use the hashtag #DirectExpansionCEFPI to tweet feedback and ask follow-up questions about Hill’s presentation.

About Direct Expansion Solutions

Direct Expansion Solutions (DXS) was created by HTS Texas in 2007 to develop a dedicated team of specialists to address the rapidly growing Variable Refrigerant Volume (VRV) segment of the air conditioning industry. Due to the rapidly growing demand for high efficiency and green building standards, DXS has experienced tremendous growth by helping owners and developers save time and money with the state-of-the-art Daikin VRV air conditioning system. DXS serves the state of Texas with offices in Austin, Dallas, Fort Worth, Houston, and San Antonio. The DXS experience includes nearly all market sectors from retail, office, residential, military, healthcare, educational and industrial applications. For more information, visit www.DXSeng.com.

First Command Banks on Energy Savings from High-Efficiency HVAC Equipment Provided by HTS Texas and Brandt

Posted on: March 26, 2012

- In: HVAC | Projects

- Leave a Comment

HTS Texas, one of the largest independent commercial HVAC manufacturers’ representatives in North America and Brandt, the largest mechanical, electrical and plumbing services provider in Texas, announced today that they have provided First Command Financial Services, Inc., with energy-efficient HVAC equipment at its corporate headquarters located at 1 FirstComm Plaza in Fort Worth, TX. The team was chosen because of a Brandt’s highly successful previous working relationship with First Command and HTS Texas’ ability to offer high-quality, energy-saving HVAC solutions.

“HTS Texas was proud to team with Brandt to quickly deliver real success for First Command’s corporate facility through the installation of high-efficiency HVAC equipment,” said Marc Tompkins, system sales representative of HTS Texas. “We believe the eco-friendly installation will provide a greener, cooler atmosphere for employees while significantly reducing their overall maintenance costs.”

First Command experienced zero business downtime because the team was able to remove and replace the building’s cooling equipment over the course of one weekend. The installation included two quiet, 200-ton, energy-efficient Daikin-McQuay Magnitude™ Magnetic Bearing Chillers and four Danfoss VLT® variable frequency drives (three 30 HP units and one 40 HP unit) providing significant energy savings.

Initial results from the installation convey a 24 percent reduction in First Command’s overall energy spend month-over-month.

“Trusted relationships with customers such as First Command are very important to Brandt so we believe in partnering with the right solutions providers to get the job done,” said Steve Hayes, senior vice president of Brandt. “We are confident First Command will reap numerous environmental and financial benefits due to the solutions provided by Brandt and HTS Texas.”

With nearly 400 employees, HTS has offices in 16 cities across the U.S. and Canada, representing more than 70 HVAC suppliers. Delivering Real Success® to all involved in its projects, HTS provides HVAC and refrigeration solutions to commercial, institutional, residential and industrial markets that represent leading manufacturers such as Daikin AC, McQuay International and Haakon Industries. For more information about HTS, visit www.htseng.com (HTS Texas http://texas.htseng.com), call toll-free at 1-866-544-1487 and connect via LinkedIn, Facebook, Twitter and Google+.

About Brandt

Are you ready to think forward? Brandt is ready to make your business operations run more efficiently, economically and reliably. For more than 60 years, we’ve helped forward-thinking business leaders design and build facilities that are energy efficient, environmentally sensitive and cost effective. From the first stages of new construction to ongoing maintenance and expert retrofitting of existing building systems, Brandt brings together more than 1,000 highly trained technicians, top caliber craftsmen and engineers and renowned technology experts to help our clients develop strategic solutions for their buildings and campuses with minimal facility downtime and maximum productivity. We’re the largest mechanical, electrical and plumbing services provider in Texas, and we also have big ideas. You can find us in Dallas, Fort Worth, San Antonio, and Austin. If you’re ready to think – and move – forward, we’re ready to take you there.

Spend your ‘Extra’ Day with HTS Texas for a ‘High Performance Rooftop Systems’ Seminar

Posted on: February 27, 2012

- In: HVAC

- Leave a Comment

On February 29th (It’s leap year!), HTS Texas is hosting a ‘High Performance Rooftop Systems’ Seminar in Austin. We’ll have a running Daikin McQuay Rebel Unit with industry leading efficiencies, a Daikin McQuay Maverick II rooftop unit and Daikin VRV system on display. Feel free to join us for either the breakfast or lunch session (lunch session is a repeat of the breakfast session). Register here!

‘High Performance VAV Systems & Controls’ Open House & Seminar in Houston

Posted on: January 30, 2012

On February 21st HTS Texas is hosting a ‘High Performance VAV Systems & Controls’ Open House & Seminar in Houston, TX. We’ll have the Award Winning ‘Delivered VAV System’ demo, a running Daikin McQuay Rebel Unit, plus industry leading solutions from Munters & Nu-Air on-site. Feel free to join us for either the morning or afternoon session (afternoon is a repeat of the morning) or just stop by to view the equipment. Register here!

- In: HVAC | Projects

- Leave a Comment

When Ernest Health, Inc. decided to build a world-class rehab facility serving the New Braunfels, Comal, Guadalupe and Hays communities, the team knew they needed to put patient comfort at the top of their priorities. This new 50,000 square foot, 40 bed rehabilitation hospital located in New Braunfels currently provides both inpatient and outpatient rehab programs for patients recovering from a variety of illnesses and injuries. Continue reading here…

- In: Events | HVAC

- Leave a Comment

Join HTS in North Texas next month as we explore High Performance Systems for Municipal and K-12 facilities. Topics will include serviceability, part availability, new industry terms & simply making your job easier! Click here to RSVP today.

HTS Texas Provides HVAC Equipment for Houston’s LEED Gold, Historic Building

Posted on: December 20, 2011

- In: HVAC | Projects

- Leave a Comment

The building to the left was recently converted into a multi-office structure from a 100-year-old rice warehouse in downtown Houston. This LEED Gold facility currently serves as a one-stop permitting center for the city as well as a permanent home for the city’s Green Building Resource Center.

The building to the left was recently converted into a multi-office structure from a 100-year-old rice warehouse in downtown Houston. This LEED Gold facility currently serves as a one-stop permitting center for the city as well as a permanent home for the city’s Green Building Resource Center.

Rounding out its downtown projects for the City of Houston, HTS Texas supplied the city’s 190,000-square-foot Central Permitting facility with:

-two 250-ton McQuay Magnitude water-cooled, frictionless chillers, which are known for their premium efficiency and quiet sound levels;

-two SEMCO Pinnacle Energy-Recovery Units– selected for their energy-saving benefits and totally integrated package;

-and a high-efficiency Daikin VRV system.

HTS Texas Cools New Headquarters for NuStar Energy L.P. with Eco-Efficient HVAC Equipment

Posted on: December 15, 2011

- In: HVAC | Projects

- Leave a Comment

HTS Texas, one of the largest independent commercial HVAC manufacturers’ representatives in North America, announced today that it is providing NuStar Energy L.P. (NYSE: NS) with energy-efficient HVAC equipment for the company’s new corporate headquarters currently under construction in San Antonio, TX. The project is being conducted in tandem with HTS Texas partners, Dynamic Systems, Inc. (DSI) of San Antonio, TX and Burns DeLatte & McCoy, Inc. (BDMI) of Houston, TX.

To effectively cool the new 293,000 square foot corporate office and meet more stringent sustainability standards, while allowing for a quieter working environment, HTS Texas will provide NuStar with eco-efficient equipment including:

- -11 custom Daikin-McQuay Vision™ air handling units with fan arrays delivering 50 degree air at a lower velocity to minimize sound;

- -two SEMCO Pinnacle® 100% outdoor air units providing a low dewpoint for humidity control;

- -one McQuay Skyline™ 100% outdoor air/make-up air unit for the kitchen designed for heavy duty construction and easy maintenance;

- -30 McQuay fan coil units and;

- -multiple variable frequency drives.

|

|

| McQuay Vision™ | SEMCO Pinnacle® |

“Through the valuable teamwork provided by HTS Texas’ project partners, DSI and BDMI, we are collectively keeping our promise to NuStar to deliver the company real success by providing the latest in green, cost-effective HVAC equipment,” said Mike Donovan, principle of HTS Texas. “Our goal for NuStar is to keep their new facility and employees “cool” for many years to come.”

About HTS

With nearly 400 employees, HTS has offices in 16 cities across the U.S. and Canada, representing more than 70 HVAC suppliers. Delivering Real Success® to all involved in its projects, HTS provides HVAC and refrigeration solutions to commercial, institutional, residential and industrial markets that represent leading manufacturers such as Daikin AC, McQuay Internationaland Haakon Industries. For more information about HTS, call toll-free at 1-866-544-1487 and connect via Facebook, LinkedIn,Twitter or Google+.

About NuStar

NuStar Energy L.P. is a publicly traded, limited partnership with 8,417 miles of pipeline; 90 terminal and storage facilities that store and distribute crude oil, refined products and specialty liquids; and two asphalt refineries and a fuels refinery with a combined throughput capacity of 118,500 barrels per day. The partnership’s combined system has over 94 million barrels of storage capacity. One of the largest asphalt refiners and marketers in the U.S. and the second largest independent liquids terminal operator in the nation, NuStar has operations in the United States, Canada, Mexico, the Netherlands, the United Kingdom and Turkey.